Industrial robot palletisers, like any complex machinery, can face several problems that can affect their performance and efficiency. Some of the common issues associated with industrial robotic palletisers, and their potential solutions include:

1. Programming errors

Problem: Incorrect or incomplete programming can lead to robotic palletisers not functioning as intended. This can result in errors in picking, placing, or stacking products, leading to misaligned or unstable pallets.

Solution: Ensure that the robotic palletiser is programmed correctly and that the software is up to date. This may involve working with experienced programmers or collaborating with the manufacturer to optimize the programming for your specific application. There are also systems available that have a tried and tested ‘easy programming’ software which helps to eliminate errors. Also, ensuring that the palletiser system has been commissioned and tested at the integrators site before being installed on your site will minimise the risk of programming errors occurring.

2. Mechanical failures

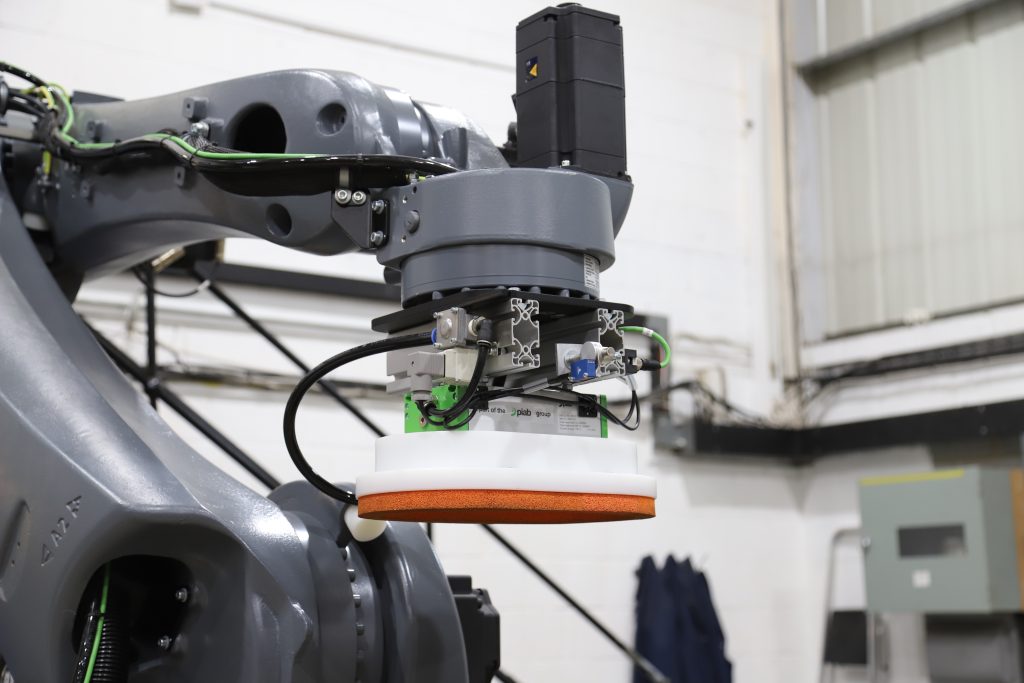

Problem: Robotic palletisers rely on various mechanical components, such as motors, gears, belts, and grippers, to perform their tasks. These components can experience wear and tear over time, leading to malfunctions, breakdowns, or reduced accuracy. Failure to perform routine maintenance tasks, such as lubrication, inspection, and cleaning, can result in increased wear and tear, decreased accuracy, and eventually, breakdowns.

Solution: Regular maintenance is crucial for the smooth operation of robotic palletisers. Implement a proactive maintenance schedule to keep the robotic palletiser in optimal working condition. This includes routine inspections, safety checks, lubrication, cleaning, and replacing worn-out components. Adherence to the manufacturer’s recommended maintenance guidelines is essential.

3. Sensor malfunctions

Problem: Robot palletisers often use sensors to detect and locate products, pallets, or obstacles in their workspace. If these sensors become faulty or misaligned, it can result in errors during the picking and placing process, leading to misplaced or dropped items.

Solution: Regularly clean and inspect the sensors to ensure their accuracy. Ensure that sensors have not got knocked or moved, and if any sensors are malfunctioning or misaligned, they should be promptly repaired or replaced.

4. Pallet or product variations

Problem: Industrial environments often involve handling a wide range of products with different shapes, sizes, and weights. If the robot palletiser is not designed or programmed to accommodate these variations, it may struggle to properly grip, lift, or stack certain products, causing errors or product damage.

Solution: If the robot palletiser struggles with handling certain products, consider adjusting or replacing the gripper to accommodate different sizes, shapes, or weights. Gripper customisation can improve the palletising process and reduce errors. If you are considering a new palletiser ensure you scope for the full range of products and ask for a demo with your products on a system before purchasing.

5. Integration challenges

Problem: Integrating a robot palletiser into an existing production line can present technical challenges. Incompatibilities with existing equipment, software, or control systems can lead to difficulties in achieving seamless integration and may require additional modifications or adjustments.

Solution: Ensure proper connectivity, compatibility, and integration to prevent communication issues. Plan any software link up required in advance of installation. Collaborate with suppliers and technicians and establish a good working relationship with the manufacturer or supplier of the robotic palletiser. They can provide valuable support, guidance, and troubleshooting assistance. Their expertise can help diagnose and resolve specific issues quickly and effectively.

To safeguard your robotic palletising system against these issues, it is important to ensure the system has been properly programmed, perform regular maintenance, and provide necessary training to operators. Additionally, involving experienced technicians and collaborating with the manufacturer or supplier of the palletiser can help diagnose and resolve specific issues efficiently. By doing this, you can enhance the performance, reliability, and efficiency of industrial robot palletisers, leading to smoother operations and improved productivity in your facility.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86