In the ever-evolving landscape of manufacturing and logistics, the demand for efficiency, precision, and adaptability has never been greater. Whether you need a high-speed palletising system for stacking large volumes, a compact palletiser for tight spaces, or a collaborative robot palletiser (cobot) our tailored solutions are built to deliver exceptional results.

1. Modular Robotic Palletising System

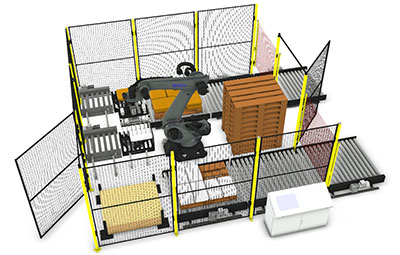

For operations demanding high speed, scalability, and flexibility, the Modular Robotic Palletising System is a robust and versatile solution. Built to handle diverse product types, weights, and pallet configurations, this system is well suited for businesses that require precision and adaptability in high-volume environments.

Key Features:

- Versatility: This system supports a wide range of palletising applications including bags, boxes, trays, shelf-ready products, etc. For higher-speed operations, row-picking and layer-forming options are available.

- Heavy-Duty Payloads: With a robust 120kg payload robot, this system manages products ranging from lightweight to heavy items with ease and consistency.

- Modular Scalability: The innovative modular design allows for seamless reconfiguration and expansion, ensuring your system evolves with your operational needs without extensive downtime or costs.

- Multi-Line Handling: Capable of processing products from multiple production lines simultaneously, this feature enhances efficiency by streamlining workflows and increasing throughput.

If you require robust, future-proof palletising with unparalleled flexibility, this system is the ultimate solution.

2. Compact Palletiser

In facilities where space is at a premium, the Compact Palletiser excels. This space-efficient system doesn’t compromise on performance, delivering high-speed palletising in a compact footprint. It is an ideal choice for businesses looking to maximise efficiency while minimising spatial demands.

Key Features:

- Autofeed Pallet System: With its fully automated pallet flow through the system, it runs continuously without interruptions for pallet removal or replacement, enhancing productivity.

- Space-Saving Design: Designed for facilities with limited space, this system combines essential functions into a compact footprint while maintaining high performance.

- Robust Performance: Handling a wide range of product types and weights, this system includes a 120kg payload robot for reliable, high-performance palletising.

- Pallet Truck Take-Off Capability: Low-profile conveyors enable pallet removal using a pallet truck or forklift, eliminating the need for extra equipment or additional floor space.

The Compact Palletiser combines efficiency and practicality, making it an ideal fit for operations that need high performance in a small footprint.

3. Cobot Palletiser

Designed to work safely alongside human operators, this system provides flexibility and efficiency. It’s perfect for palletising lightweight products in environments where safety and ease of use are critical.

Key Features:

- Dual-Mode Functionality: This cobot transitions seamlessly between collaborative and industrial robot modes, ensuring optimal performance while maintaining safety.

- Built for Durability: Featuring a 30kg payload capacity, the cobot is engineered for demanding environments and continuous operation.

- Advanced Safety Systems: Equipped with intelligent force sensing, it halts operation upon detecting unexpected interactions, ensuring a safe working environment.

- Customisable Design: Choose from various grippers and safety configurations, including guarding options and area scanners, to meet your specific requirements.

The Cobot Palletiser is the ideal solution for palletising lightweight products off slower speed production lines.

Easy Programming Software: Simple, Powerful, Efficient

All of our robotic palletising systems come equipped with intuitive, user-friendly easy programming software. This patented software enables you to reprogramming the palletising system quickly and efficiently for different product sizes and stack configurations, without requiring advanced technical expertise.

Key Features:

- Optimised Stacking Patterns: Automatically generated stacking configurations enable you to choose the most efficient stack pattern for your product. Maximising pallet space and storage efficiency.

- Rapid Adjustments: Switch between product sizes or pallet layouts in minutes, ensuring flexibility during production shifts.

- Intuitive User Interface: Simplifies complex programming tasks, enabling operators to make adjustments with minimal training.

- Multi-Picking Automation: The system automatically rotates and groups products for efficient multi-picking or row gripping.

This combination of advanced technology and simplicity ensures businesses can quickly adapt to changing demands without costly downtime.

Whether you’re a small-scale operation or a large industrial facility, our palletising solutions have been designed to evolve with your needs.

Contact us today on 01223 499488 or helpline@granta-automation.co.uk to discuss your requirements and discover how we can help you optimise your palletising processes.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86