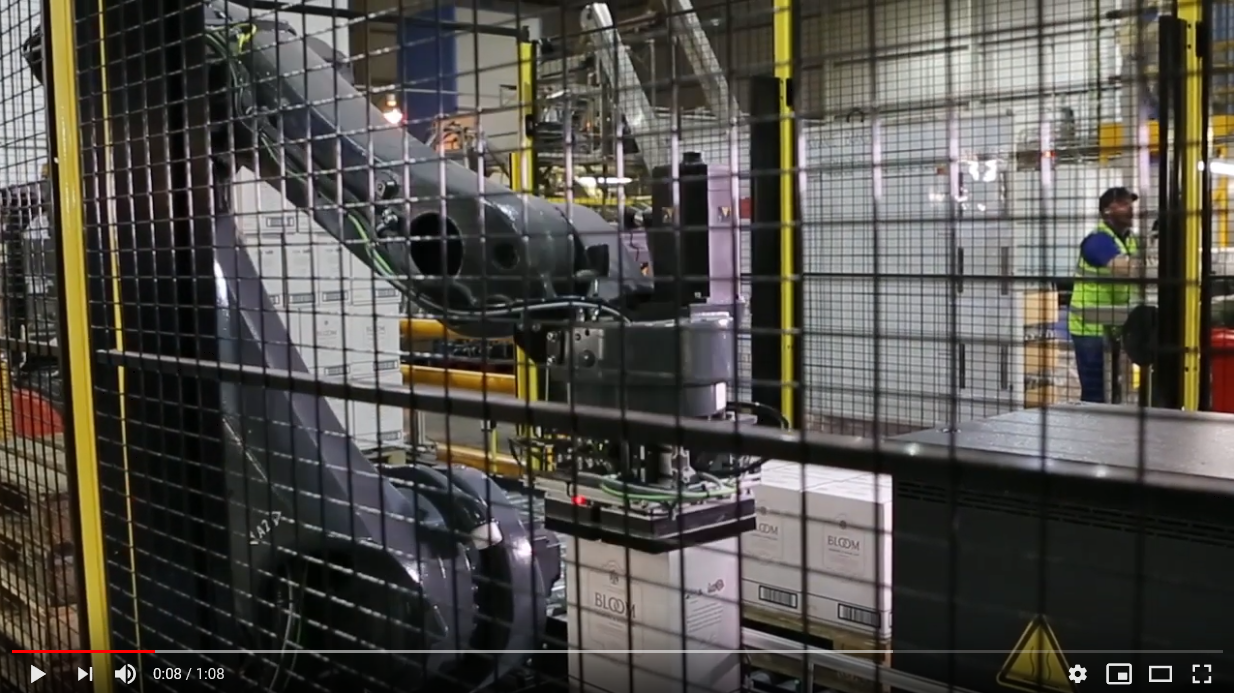

Automated palletising is a machine or system that stacks products onto pallets. Palletisers may be either robotic or mechanical, and goods will usually be picked and placed as individual products or as a complete layer.

Automated palletising is a machine or system that stacks products onto pallets. Palletisers may be either robotic or mechanical, and goods will usually be picked and placed as individual products or as a complete layer.

There are many advantages and disadvantages of automated palletising and these are explained here in more detail.

Disadvantages of Automated Palletising

- Capital Expenditure

Automated palletising systems usually yield a positive ROI very quickly, however there is still always the need for an initial capital outlay. Before making a decision we recommend you consider both the investment needed and also the ROI you expect to achieve. When calculating ROI it is important to calculate the value of both the tangible and intangible benefits before deciding whether there is a business case for investment. Another alternative is to look at hiring or leasing the palletising system rather than making an outright purchase. Often the hire or leasing cost is less per month than the saving you will make.

- Gets Rid of Jobs

This is indeed true that with the introduction of automated palletising, staff will no longer be required to palletise your products. However, statistics have shown that many companies have been able to re-train their staff to enable them to work in other areas of the business. Many companies have also found that after introducing automation and improving the throughput of their production process, their sales have risen, thus creating more jobs in different parts of the business. Staff morale is usually higher after implementing automation.

- Re-Programming Can Be Expensive When Product or Production Process Changes

In most cases, when a product size or production process changes, a costly programmer is required to re-program the automated palletising system. However, with today’s advances in technology, there are now automated palletising systems available that can be re-programmed by your factory floor staff (see Granta Automation easy program palletiser). It is also possible to purchase modular palletising systems that can be quickly and easily moved and re-configured within your factory as and when your production process changes. Systems such as these ensure that your automated palletising system does not become redundant when your production process or product changes.

Advantages of Automated Palletising

- Improved Working Environment

Automated palletising improves the working conditions and safety within your production process or plant by eliminating the manual handling element of palletising and therefore removing the rise of repetitive strain injuries occurring. This in turn will significantly reduce the risk of RSI claims occurring and make a safer working environment for your staff.

- Cost Effectiveness

Automated palletising systems can be programmed to run in sync with your production process. This means that for as many hours of the day that there are products coming off your production line, the automated palletiser will be palletising them. There is also no production downtime due to breaks, holidays or sick leave as the manual element of palletising has been removed. Removing these unplanned downtimes improves the OEE of your production process and increases throughput, thus increasing your profits.

- Effective Across Multiple Production Lines

Depending on the layout of your production process you may have multiple palletising stations within your factory. This may mean that you need to have a person stationed at the end of each production process, but due to the speed of the product coming off the machine, they are not busy all of the time. This in itself creates an inefficiency in the process as you are effectively having to pay for wasted time/labour. With an automated palletising system it is possible to use one system for palletising off multiple production processes, thus increasing efficiencies.

- Improve Product Quality

Automated palletising also results in less damaged product leaving your factory. This has a twofold benefit as it not only improves your customer service due to improved product quality, but also means you are less likely to receive damaged goods claims and returns.

- No Labour Crisis

Recruiting for repetitive, manual labour tasks such as palletising is becoming increasingly difficult in the current environment. Installation of an automated palletising system eliminates the need to recruit for this role.

- Payback On Investment

Installing an automated palletising system usually has a very quick payback time as you are saving costs on labour as well as improving your efficiencies. Download our free Automation Project Payback Calculator to find out what the payback time would be for your process.

If you would like any further help on the advantages or disadvantages of automated palletisers, please contact us on 01223 499488 or helpline@granta-automation.co.uk.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86