Palletising boxes may seem like a simple process, but when it comes to scaling production, reducing costs, and ensuring consistency, the palletiser you choose can make or break your efficiency. With many different palletising systems on the market, how do you decide which is the best fit for your business?

At Granta Automation, we focus on three main types of palletisers: Modular Robotic Palletisers, Compact Palletisers, and Cobot Palletisers. Each has its own strengths, and best-use cases.

This guide provides a complete overview of the different palletiser types, including features, benefits, and ROI considerations, to help you make the right decision for your business.

Why Automate Box Palletising?

Before diving into the system types, its worth understanding why automation is so valuable in box palletising.

Key Benefits of Automated Palletising

- Labour savings: Reduce reliance on manual handling, especially in high-turnover environments.

- Health & safety improvements: Eliminate repetitive strain injuries and heavy lifting tasks.

- Consistency & stability: Automated systems stack boxes in neat, repeatable patterns.

- Speed & throughput: Systems can work faster and for longer hours than manual labour.

- Scalability: As production grows, automation can be scaled to meet demand.

With rising labour costs and increasing health and safety regulations, many companies now see automated palletising as not just a cost-saver, but a necessity.

The Three Main Palletiser Systems for Boxes

The modular robotic palletiser is a high-performance, flexible solution designed for heavy-duty and high-speed palletising. Its modular design makes it highly scalable, allowing businesses to add or reconfigure elements as production demands grow.

Features

- Payload: Up to 140 kg

- Product types: Boxes, cartons, trays, and even bags

- Configuration: Can perform single pick, row picking or full layer forming

- Scalability: Modular design allows for future expansion

- Speed: High throughput suitable for 24/7 production

- Programming: Very easy to reconfigure for new pallet patterns or products using the simple easy programming software interface

Advantages

- Handles a wide variety of products and pallet patterns

- Excellent for high payload and high-volume lines

- Very reliable and durable for industrial use

- Flexible enough to adapt to changing production layouts

- Can be used to palletise off multiple production lines

Limitations

- Larger footprint required

- Higher initial investment

- Not designed for pallet truck take-off

Best For

Large-scale operations where speed, payload capacity, and scalability are the top priorities.

The Compact Palletiser is ideal for businesses that need robust automation in a small footprint. It integrates pallet truck removal, automatic pallet feeding, and box handling into a streamlined design.

Features

- Payload: Up to 140 kg

- Product types: Boxes, cartons, trays, and even bags

- Configuration: Can perform single pick or row pick

- Footprint: Very compact design, smaller than traditional robot cells

- Integration: Built-in infeed conveyors and automated pallet handling

- Programming: Very easy to reconfigure for new pallet patterns or products using the simple easy programming software interface

Advantages

- Takes up very little floor space

- Excellent for heavy loads and high-volume lines

- Highly reliable and durable for industrial use

- Can be used to palletise off multiple production lines

Limitations

- Less future-proof than modular systems

- Limited expandability for future expansion

Best For

Manufacturers with restricted floor space that still need strong, reliable palletising performance with pallet truck take off.

The Cobot Palletiser uses collaborative robot technology to palletise boxes safely alongside human workers. It is designed for flexibility and ease of use, making it perfect for businesses handling varied products or smaller batch sizes.

Features

- Payload: Up to 30 kg

- Safety: Force-limited, with built-in sensors

- Operation modes: Collaborative (safe to run alongside people) or industrial speed (when full safety is in place)

- Programming: Very easy to reconfigure for new pallet patterns or products using the simple easy programming software interface

- Footprint: Compact, fits into smaller production spaces

- Moveable: Can be moved between production lines

Advantages

- Low-cost entry into automated palletising

- Excellent flexibility for use on multiple lines and frequent product changeovers

- Safe to use alongside people

Limitations

- Lower throughput compared to larger industrial robots as only single items can be picked

- Limited payload (not suited for very heavy boxes)

Best For

Businesses needing flexibility, safety, and ease of use.

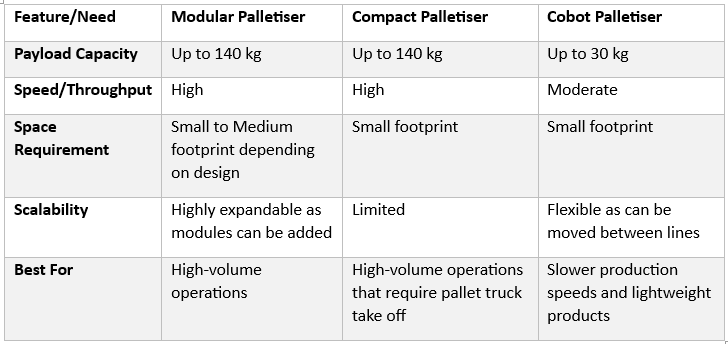

Side-by-Side Comparison

ROI and Payback Considerations

Automating palletising often delivers a fast return on investment, but ROI will vary by system type and production environment.

Key ROI Factors

- Labour savings: Fewer staff required for repetitive stacking tasks.

- Injury reduction: Lower costs associated with manual handling injuries.

- Increased throughput: More pallets per shift, fewer bottlenecks.

- Flexibility gains: Ability to switch quickly between product types and reduce downtime.

Typical ROI:

While ROI timelines can vary based on factors such as the specific industry, production volume, and overall operational efficiency, many businesses begin to see a payback period ranging from 12 to 24 months. Some forward-thinking manufacturers even achieve full ROI in less than 12 months, which positions robotic palletisers as a highly cost-effective solution in the long term.

Frequently Asked Questions

Q: Can one palletiser handle multiple box sizes?

Yes – all Granta palletisers come with easy programming software which enables factory staff to reprogram the palletiser for different box sizes/stack patterns within minutes.

Q: What if my production grows in the future?

A modular palletiser is a good choice for scalability as it can be expanded as your production increases, ensuring long-term flexibility. Compact and Cobot systems can manage growth to a certain extent, but they are less expandable. However, in many cases, palletiser systems are initially installed well below their maximum run capacity, giving you room to grow before needing an upgrade.

Q: How long does installation take?

It depends on the complexity of the system being installed, but typically the initial install will be completed in about a week, with commissioning then taking place after this.

Q: Do palletisers require safety guarding?

Modular and compact palletiser systems require guarding, and cobot palletisers can operate without guarding depending on the application and speeds required.

Conclusion

The ‘best’ palletiser for your operation depends on your unique requirements:

- Modular Palletiser – High speed, handles heavy loads, and easily scalable for future growth.

- Compact Palletiser – Space-saving design with pallet truck take-off and high-speed operation.

- Cobot Palletiser – Flexible, safe, and ideal for low-payload products.

By carefully aligning your production needs with the right system, you can achieve significant efficiency gains, reduce manual handling risks, and ensure your investment delivers long-term value.

In addition, all three palletiser types are powered by our unique Easy Programming software. Unlike traditional systems that often require specialist coding knowledge, this intuitive software uses a simple graphical interface that enables operators to set up or adjust pallet patterns within minutes, with minimal training. From drag-and-drop configuration to rapid re-setups when box sizes or pallet formats change, the software ensures maximum flexibility and minimal downtime. This means your palletiser is not only the best fit today, but can also adapt easily as your production needs evolve.

Call us on 01223 499488 or helpline@granta-automation.co.uk, to discuss the best palletising solution for your application.