The “best” palletiser for use in the food industry can vary greatly depending on your specific needs, production volume, space constraints, and the type of food products you’re dealing with. There isn’t a one-size-fits-all answer. However, there are a several generic factors that are important to consider which are listed below.

- Type of Food Product: Different food products have varying shapes, sizes, and packaging requirements. Some palletisers are better suited for handling specific types of food, such as bottles, boxes, bags, or cans. There are multiple gripper types available to suit different applications and the type of gripper you will need will depend on the products attributes

- Throughput and Speed: Depending on your production volume, you’ll need a palletiser that can handle your required throughput. Collating technology and multi product gripping may be required for higher speed applications. This may involve picking and placing a row of product at a time, or picking and placing complete layers.

- Automation Level: Automated palletisers range from systems that require manual placing of empty pallets and removal of full pallets, through to fully automated cells that include automated pallet feeding and slipsheet placement, with full pallets being fed out of the cell, enabling the system to continuously run. The level of automation you choose will depend on your budget, available space, and labor resources.

- Footprint and Layout: Consider the available space in your facility and the layout of your production process. It is importance to consider infeeds and outfeeds to the palletiser, access requirements for existing machinery, and fork lift/pallet truck access for removing finished pallets of product from the system.

- Flexibility: The ability to handle various packaging configurations and adapt to different products can be important, especially if you produce a wide range of food items.

- Maintenance and Reliability: Look for a palletiser that is known for its reliability and ease of maintenance to minimize downtime. It is also important to choose a company that has a good support system available, including both on site and remote support options.

- Integration: Ensure that the palletiser can easily integrate with your existing production line equipment and software systems.

- Safety: Palletisers should adhere to safety regulations and have features that protect operators and prevent accidents.

- Future proof: Ensure that the system you choose is future proof and can be modified as your requirements change. A modular system is the best type of system for this.

Based on these factors, there are several types of palletisers commonly used in the food industry:

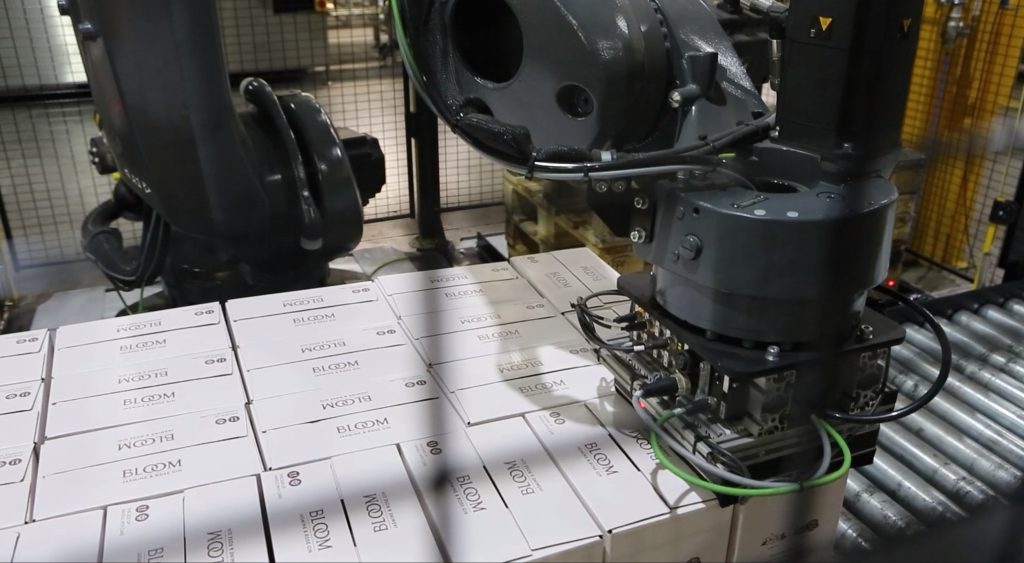

- Robotic Palletisers: Robotic palletisers use industrial robots to pick, place, and stack products onto pallets. They are highly versatile and can handle various product types and sizes. Robotic palletisers are often used in industries with frequent product changes.

- Layer Palletisers: Layer palletisers are designed to stack entire layers of products onto pallets at once. They are commonly used for products that are palletised in consistent layers, such as cases of beverages or boxes.

- Bag Palletisers: These palletisers are specialised for handling bags of various sizes and shapes, such as sacks of flour, pet food, or fertilizer. They can use robotic arms or mechanical systems to stack bags onto pallets.

- Case Palletisers: Case palletisers are designed to handle individual cases or boxes of products, often found in industries like food and beverage, pharmaceuticals, or consumer goods. They can be equipped with various end-of-arm tools, such as vacuum grippers or clamps. Row grippers and layer formers can also be used to enable the palletiser to lift multiples or complete layers of product at a time.

- De-palletisers: While not exactly palletisers, de-palletisers are machines used to remove products or materials from pallets. They are often used in industries like recycling or food and beverage to unload products from incoming pallets.

- High-Level Palletisers: These palletisers are typically used in industries with high production rates. They can stack products at high speeds and are often integrated into conveyor systems. High-level palletisers can be either robotic or conventional machines.

- Low-Level Palletisers: Low-level palletisers are usually smaller and operate at lower speeds compared to high-level palletisers. They are commonly used in smaller production facilities or when cost considerations are a priority.

- Mixed-Load Palletisers: These systems are designed to create mixed-load pallets with multiple product types or SKUs on the same pallet. They are commonly used in distribution centres and warehouses.

Remember that the best palletiser for your food industry needs depends on a careful assessment of your production line, the type of food products you’re working with, your budget, available space, and your desired level of automation. It’s recommended to reach out to manufacturers, discuss your requirements in detail, and potentially request demonstrations or references to find the most suitable palletiser for your specific situation.

If you would like to discuss your specific application in more detail, please contact us on 01223 499488 or helpline@granta-automation.co.uk.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86