There are many different types of products that a robotic palletiser system can handle. From cartons, boxes, bags, bottles, and collation trays, right through to open top crates and display boxes. However, a robotic palletiser is not limited to just these types of products.

With a robotic palletising system, the robot gripper or head is designed to suit the type of product being lifted. There are many different varieties of gripper head and bespoke grippers can be created to pick and place product if a standard gripper is not suitable for the product. Below is a brief summary of product types and the type of grippers that are used to pick and place them with palletising.

Vacuum Gripper

A vacuum gripper picks and places using vacuum so it is well suited to products with a flat, non porous surface area. It may pick one product at a time or multiple products at a time depending on the speed requirements of the production line. Products that can be picked and placed using a vacuum gripper include:

- Boxes

- Cartons

- Display boxes

- Some types of bags

- Panels

- Sheets

- Boards

Bag Gripper

A bag gripper has positioning pins, lifting pins and a centre clamp which hold and support the bag as it is being picked and placed. Products that can be picked and placed using a bag gripper include:

- Bags

- Sacks

A bag gripper will be able to pick and place bags and sacks of any material type; such as plastic, paper, hessian etc.

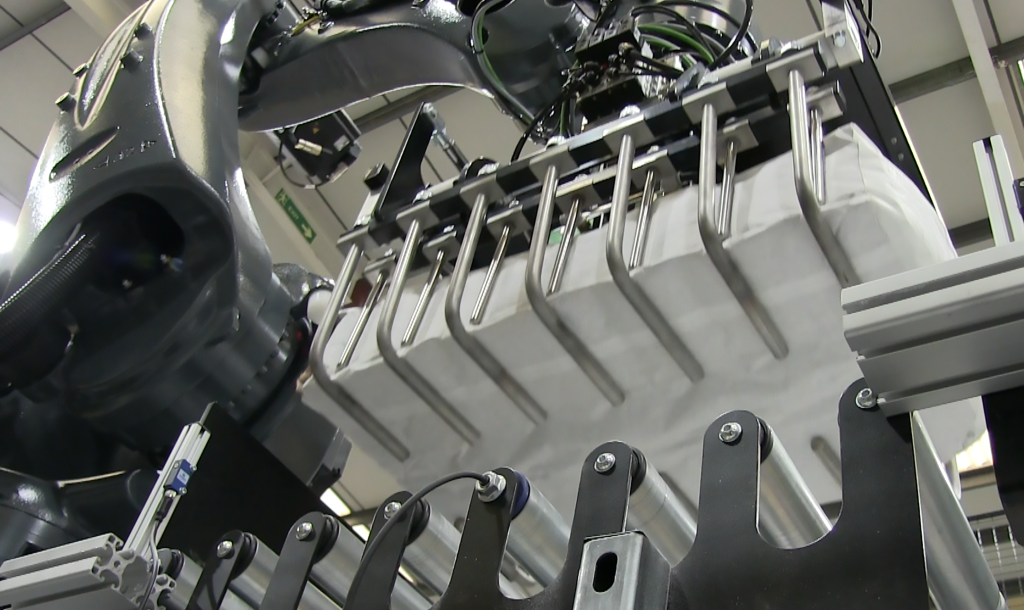

Underneath Gripper

An underneath gripper works by sliding the product onto tines, and then gripping the top of the product whilst it is being picked and placed. This type of gripper is usually used where the product is fragile, or can’t be picked and placed using vacuum or a bag gripper. Products that can be picked and placed using an underneath gripper include:

- Heavy cartons or boxes

- Boxes that are not suitable for vacuum picking

- Bags that can’t be picked and placed with a bag gripper or vacuum picked

- Collation trays

- Open top boxes

- Display boxes

- Open top plastic crates

- Open top cardboard crates

- Shrink wrapped items

- Packs of bottles

Parallel Gripper

A parallel gripper picks and places items using two parallel plates that close in against the items sides to grip it whilst it is being picked and placed. Products that can be picked and placed by a parallel gripper include:

- Boxes

- Shrink wrapped trays of goods

- Display boxes

Bespoke Gripper

A bespoke gripper is specifically designed to pick and place a particular product. They usually clamp the product in some format, and this clamp is then released once the product has been picked and placed. Products that are usually picked and placed with a bespoke gripper include:

- Large bottles, ie. 3 litre or 5 litre bottles

- Drums

- Cans

- Irregular shaped items

- Very heavy items

- Very large items

- Fragile items

As you can see, a robotic palletiser can handle a virtually unlimited number of different product types! The type of gripper used in each application will depend on the product type being palletised along with the palletising speeds that are required.

If you would like to know if your product would be suitable for automated palletising then feel free to get in touch with us on 01223 499488 or contact us at helpline@granta-automation.co.uk. We will also be very happy to arrange a free trial of your product on a palletiser if you require this.

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 81

Warning: Undefined variable $aria_req in /var/www/granta-automation.co.uk/news/wp-content/themes/twentyten/comments.php on line 86