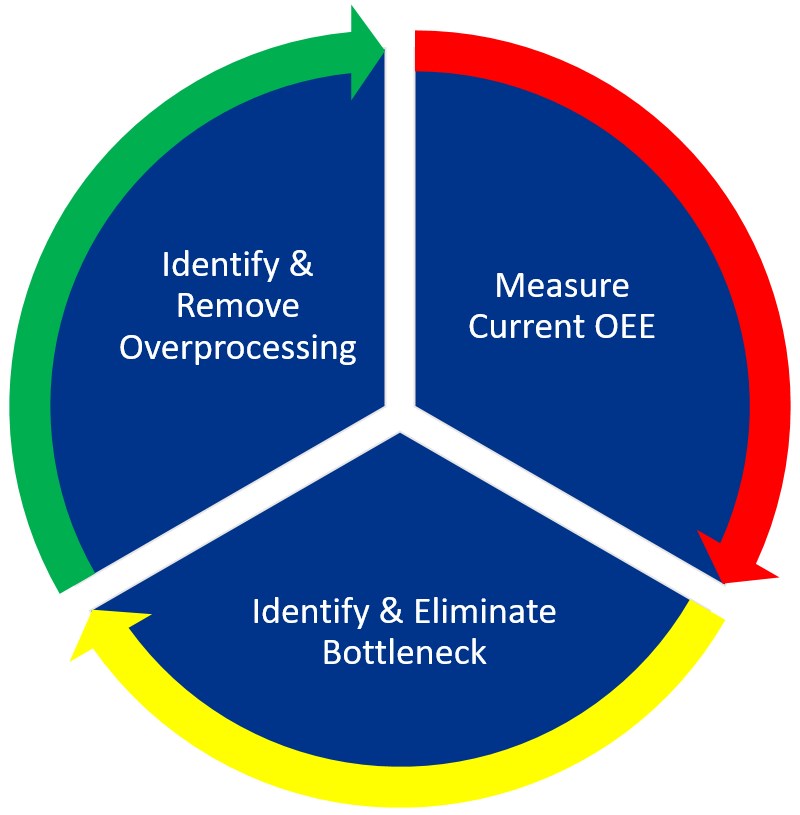

Having got here, you’re now only 3 steps away from improved OEE!

All too often it’s easy to over think things when it comes to improving OEE in production. A lot of time is often spent analysing the current process and then you can end up with so much data that it’s difficult to know where to start!

To improve OEE effectively, it’s best to analyse small parts of your production process at a time. You may wish to concentrate on just one machine, or you may wish to analyse a complete process for a particular product. Trying to analyse your complete manufacturing process in one hit typically ends up creating more action points than you can execute, so very little gets executed. Analysing the process in small chunks allows you to track progress more easily and create meaningful action points that can be executed and monitored.

Step 1 – Measure Current OEE

Before you begin making improvements it’s important to measure the current OEE of the particular process you are going to work on first. This gives you a benchmark from which to measure the success of the improvements you make. It’s worth taking several OEE measurements at different times of day and on different days of the week, as this will show you any fluctuations in efficiency and may well point up the bottleneck that you need to eliminate. Information on how to measure and calculate OEE, along with a downloadable OEE calculator is available here.

Step 2 – Identify & Eliminate Bottleneck

Having calculated the current OEE, you can now begin work on identifying the bottleneck in the process you are analysing.

Bottleneck machines or processes are often easily identified as they have a build-up of parts waiting to be processed by them. If your bottleneck is not so obvious, then it is best to create a flow chart showing the step by step processes that are involved in producing the particular product or part you are analysing. Having completed a flow chart, you will then have an idea as to where in the process the bottleneck may be occurring, and you will be able to investigate this area further to see exactly where the bottleneck is.

Think broad, for example it may not be the speed of the machine when it is actually running, it may be the changeover time that drags a machine’s overall throughput down.

Having identified the bottleneck, the next step is to exploit the bottleneck. Do you need to increase the capacity of the bottleneck, or check parts before they enter the bottleneck so that there is no work being processed by the bottleneck that will be rejected further down the process? More information on identifying and eliminating bottlenecks is available here.

Step 3 – Identify & Remove Overprocessing

Overprocessing is something that often gets overlooked when trying to improve OEE. Creating a flow chart of the process that you’re analysing and then asking the ‘5 Whys’ for each part of the process should help you to identify any overprocessing of the product. eg.

- Why does this part take 30 seconds to package? Because we use a 3 part packaging process; a locator cut out card is placed inside the box, the box is then closed and passed through a shrink wrap machine.

- Why do we use this 3 part packing process? To make sure the part isn’t damaged when it arrives at the customer.

- Why does it need all 3 parts of the packing process? The locator card is to hold it still in the box and the plastic wrap is to stop the cardboard going soggy if it gets damp.

- Why does the part need to be held still? Because it is smaller than the box and will get damaged if it rattles around inside the box during transit.

- Why can’t we use a smaller box or box net that includes the locator as part of it? We could try using a smaller box or easily modify the box net to include the locator in it. This would save time when packing.

From this example, you can see how asking the 5 Whys will lead you through the process of analysing why you are doing what you are doing. All too often processes can evolve over time and just become ‘the way things are done’ and nobody questions it. Over time certain processes may actually become unnecessary, or may be able to be done in a more efficient way.

Having carried out these 3 steps, it is now important to return to step one and measure your OEE again as this will give you a measure of the improvements that have been made. If you have been analysing a process, you may want to re-analyse the same process again to eliminate further bottlenecks, or you may then wish to move on to another area of your manufacturing process.

If you find from your analysis that palletising is one of your bottlenecks then feel free to get in touch and we’ll be happy to help, contact us on 01223 499488 or helpline@granta-automation.co.uk