In an era where operational excellence defines competitive advantage, leveraging automation technologies has become essential for businesses aiming to streamline workflows and boost productivity. One of the most powerful tools to achieve these goals is the Automated Guided Vehicle (AGV). AGVs are revolutionising the way materials are moved across warehouses, factories, and distribution centres, enabling smarter, faster, and more reliable operations. But what exactly is an AGV — and why should your business consider investing in this cutting-edge automation technology?

Defining Automated Guided Vehicles (AGVs)

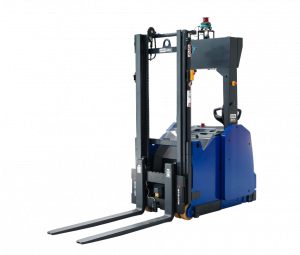

Unlike traditional forklifts or pallet trucks that rely on human operators, AGVs use advanced navigation technologies, including a 360° field of view that continuously detects their surroundings. This allows them to manoeuvre safely and precisely along predetermined routes without human intervention.

AGVs come in many forms and sizes, capable of carrying anything from small parts to large pallets. Whether you operate in automotive manufacturing, food and beverage, pharmaceuticals, or logistics, there is an AGV solution tailored to streamline your material handling processes.

How AGVs Transform Material Handling

At their core, AGVs are programmed to follow defined routes within your facility, stopping exactly where materials need to be picked up or dropped off. This eliminates the variability and inefficiency of manual transport and ensures consistent workflow across your operations.

Beyond simple navigation, AGVs are integrated with facility-wide automation systems — such as Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES) — allowing them to communicate with other AGVs and equipment. This intelligent connectivity enables a synchronised network of vehicles that adapt dynamically to changes in production schedules or inventory demands, reducing bottlenecks and downtime.

The Compelling Benefits of AGVs

1. Significant Cost Savings:

AGVs reduce dependency on manual labour for repetitive transport tasks. This not only cuts labour costs but also lowers expenses related to injuries and accidents caused by human error. The predictable and continuous operation of AGVs means your facility can achieve higher throughput without proportional increases in overhead.

2. Enhanced Operational Efficiency:

AGVs operate around the clock without fatigue, maintaining consistent speed and precision. This results in faster material transport, reduced waiting times, and smoother production cycles — all crucial for meeting tight delivery deadlines and customer expectations.

3. Improved Workplace Safety:

With built-in obstacle detection, collision avoidance, and emergency stop functions, AGVs dramatically reduce risks associated with forklift accidents and manual handling injuries. In fact, improved safety and the reduction of forklift-related collisions are the number one reasons many organizations invest in AMRs and AGVs. By minimizing the chances of human error and unsafe interactions between people and heavy equipment, these systems foster a safer working environment, protecting both personnel and valuable assets.

4. Minimised Errors and Enhanced Quality:

Automated material handling removes the human factor from transport tasks, greatly reducing errors such as misplaced goods or incorrect deliveries. This leads to fewer production disruptions, less waste, and improved overall product quality.

5. Scalability and Flexibility for Future Growth:

As your business grows or evolves, AGVs can be reprogrammed or added to your fleet with minimal disruption. This modular approach to automation means your investment remains adaptable to shifting operational demands and emerging technologies.

Take the Next Step Toward Automation Excellence

Investing in Automated Guided Vehicles is a strategic move that can transform your material handling processes and propel your business toward greater efficiency, safety, and profitability. As automation technology continues to advance, early adopters of AGVs are positioning themselves for long-term success in a highly competitive marketplace.

Discover how Granta Automation can help you unlock the full potential of AGVs. Visit our AGV solutions page to learn more or contact us at helpline@granta-automation.co.uk. We will be very happy to help.

Find out more…

- Ways To Speed Up The Palletising Process In Production

- How To Automate Cross Palletising and Depalletising from UK to Euro Pallets

- How Cycle Time Reduction Improves Operational Efficiency

- Autonomous Mobile Robot (AMR) Pallet Stations, Charging Stations, and Conveyor Stations

- Mastering Budget Planning: Advanced Methods for Planning and Allocating Capital Budgets in Manufacturing