As we approach 2026, manufacturers and warehouse operators are increasingly looking for ways to improve efficiency, reduce costs, and adapt to evolving workforce dynamics. Automation continues to play a pivotal role in achieving these goals, and at Granta Automation, we specialise in helping companies implement solutions that make a measurable impact.

Two technologies in particular—palletisers and autonomous mobile robots (AMRs)—have emerged as key drivers of operational excellence. Whether it’s streamlining end-of-line packaging or optimising intralogistics, these solutions can transform the way your facility operates.

Why Automation Planning Matters Now

Capital expenditure planning doesn’t happen overnight. Automation projects, whether installing a robotic palletiser or deploying a fleet of AMRs, require careful consideration of workflow, space, integration with existing systems, and ROI. Planning early not only ensures a smoother implementation but also helps secure budget approvals and avoid last-minute cost surprises.

By beginning discussions now, your team can evaluate the right technology for your needs, define KPIs, and create a roadmap for deployment in 2026. This proactive approach can lead to significant efficiency gains and set your operation apart from competitors.

Palletisers: Choosing the Right System for Your Operation

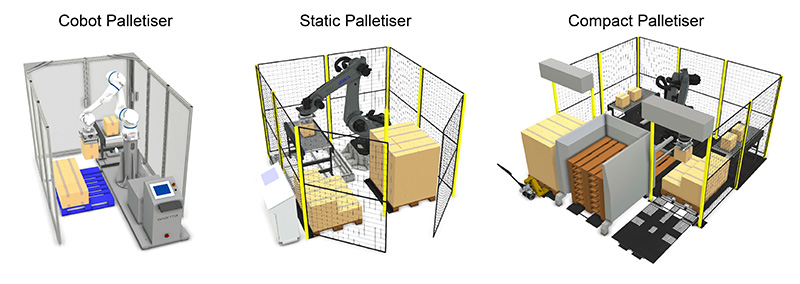

Granta Automation offers a range of palletiser solutions designed to meet diverse production needs while maximising efficiency and flexibility. Our portfolio includes:

Modular Palletisers

- Versatile and flexible: suitable for standard pick-and-place palletising of bags or boxes, high-speed layer-forming palletising, and automated container unloading

- Fully automated programming option for facilities that frequently change product sizes, allowing the system to automatically set up pallet stack patterns and program the robot

- Quick reconfiguration: modular design allows the system to adapt to changing production requirements

- Short lead times and fast installation thanks to its modular architecture

- Applications: ideal for end-of-line palletising as well as container unloading and palletising

The Modular Palletiser is designed with industrial needs in mind, providing maximum flexibility and efficiency while simplifying operations and minimising downtime. It’s a robust solution for facilities that require versatility and adaptability across multiple product types and production lines.

Compact Palletisers

- Very compact design ideal for facilities with limited floor space

- Pallet truck take-off – designed to allow pallets to be removed using a pallet truck

- 140kg payload robot capable of handling a wide range of products

- Variety of gripper options available to suit different product types

- Quick installation to minimize downtime and speed up deployment

This system is perfect for high-speed, small-to-medium production lines where space is at a premium but efficiency and flexibility are still critical.

Cobot Palletisers

- 30kg payload collaborative robot, ideal for lighter product handling

- Sturdy industrial-grade design built for 24/7 operation

- Variety of gripper options to accommodate different product types

- Quick installation to minimize downtime

- Available with or without guarding, depending on facility requirements

- Intelligent force sensing for collaborative operation:

- In collaborative mode, the cobot works safely alongside human operators, running at slower speeds and stopping immediately if unexpected forces are detected

- When full safety guarding is in place, it operates at full industrial speeds for maximum efficiency

The cobot’s flexibility allows it to seamlessly switch between safe, human-collaborative operation and high-speed industrial mode, making it a versatile solution for facilities that require both productivity and safety.

Each system is designed to streamline your palletising process, reduce manual handling, and increase productivity. Whether you need a scalable modular solution, a compact high-speed system, or a collaborative cobot setup, Granta Automation has a solution to match your operational requirements.

Easy Programming Software: Simple, Powerful, Efficient

All of our robotic palletising systems come with our user-friendly, easy programming software. This patented software enables you to reprogramming the palletising system quickly and efficiently for different product sizes and stack configurations, without requiring advanced technical expertise.

Key Features:

- Optimised Stacking Patterns: Automatically generated stacking configurations enable you to choose the most efficient stack pattern for your product. Maximising pallet space and storage efficiency.

- Rapid Adjustments: Switch between product sizes or pallet layouts in minutes, ensuring flexibility during production shifts.

- Intuitive User Interface: Simplifies complex programming tasks, enabling operators to make adjustments with minimal training.

- Multi-Picking Automation: The system automatically rotates and groups products for efficient multi-picking or row gripping.

This cutting-edge AI technology makes automated palletising viable for very short production runs, as little as one pallet load, by removing the prohibitive setup time.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are transforming intralogistics by moving materials safely and efficiently across warehouses and production floors. Unlike traditional conveyor systems or forklifts, AMRs adapt dynamically to changing environments, reducing congestion and operational bottlenecks.

Granta Automation’s AMR systems provide flexible, safe, and efficient solutions for material handling and intralogistics. Key features include:

- Easy integration and deployment, allowing rapid implementation into existing operations

- Advanced safety features: 360° laser, 3D cameras, and mechanical bumper for secure navigation around people and obstacles

- Efficient charging: fully charges in just 45 minutes

- High performance: maximum speed of 4.9 mph and a 1200 kg payload capacity

- Smart navigation: if a path is blocked, the AMR automatically circumnavigates obstacles and recalculates a new route

- GoControl software: web-based interface accessible from any device to manage orders, prioritise tasks, and dispatch AMRs

- Displays physical infrastructure (pallet stations, charging stations, conveyors) and virtual infrastructure (parking spots, traffic control zones)

- Tracks robot location, load status, and destination in real time

- Easily editable maps allow adding, removing, or rearranging components

These AMRs are ideal for a variety of applications, from transporting heavy pallets across warehouse floors to integrating with production lines for continuous material flow. Their intelligent routing and robust safety systems ensure reliable operation, even in dynamic environments.

Supporting Your 2026 CapEx Planning

If you’re considering Palletisers or AMRs for 2026, Granta Automation can help you evaluate options and provide a budgetary quote tailored to your operation. This allows you to make informed decisions, align your investments with strategic goals, and confidently plan your capital expenditure.

Planning ahead also ensures you can explore innovative configurations, evaluate ROI, and minimise disruption during implementation. Early engagement with Granta Automation gives your team the insights and guidance needed to deploy automation solutions efficiently and effectively.

Take the Next Step

Automation is no longer a future concept—it’s a practical solution that drives measurable results today. If you have projects planned for 2026 involving palletisers or AMRs, now is the time to start planning. You may find these tools useful in helping you to calculate ROI.

- Palletiser Savings Estimator – https://www.granta-automation.co.uk/palletiser-savings-estimator

- Payback Calculator – https://www.granta-automation.co.uk/automation-project-payback-calculator

- Budget Quote Request – https://www.granta-automation.co.uk/project-builder

Contact us on 01223 499488 or helpline@granta-automation.co.uk to discuss your upcoming projects, explore potential solutions, and receive a budget quote to support your CapEx planning. Together, we can help you build a more efficient, safer, and future-ready operation.

Find out more…

- Grantas Portable Cobot Palletising System: High-Performance Automation That Moves With You

- Manual vs. Automatic Palletising: A Comprehensive Comparison

- Manufacturing Efficiency: Why Every Second (and Every Pound) Counts

- The Hidden Costs of Downtime in Food & Beverage Production

- How Robotic Palletisers Deliver Fast ROI for Manufacturers