As modern automation systems become more interconnected, data‑driven, and business‑critical, integration decisions have shifted from being purely technical to deeply strategic. Yet many organisations still evaluate the choice between in‑house integration and hiring an expert integrator through a narrow financial lens.

Hourly rates versus salaries. External fees versus internal headcount.

This comparison feels intuitive—but it is incomplete. In many cases, it is misleading.

The true cost of integration is not defined by what you pay to build a system. It is defined by what you pay to own, operate, adapt, and recover from that system over its entire lifecycle.

When viewed through that broader lens, the economics of integration look very different.

Why In‑House Integration Appears Cheaper—Initially

There are valid reasons organisations gravitate toward internal integration:

- Existing engineers already understand the process

- Internal resources feel “paid for”

- Teams retain direct control over priorities

- Knowledge stays inside the business

For small, incremental changes, this approach can be efficient. Internal teams can respond quickly, avoid procurement cycles, and make adjustments without external coordination.

But as project complexity grows, the apparent cost advantage of in‑house integration erodes rapidly.

The Hidden Costs Most Teams Never Model

The largest cost drivers of in‑house integration rarely appear in budgets, proposals, or project justifications. They emerge later—quietly, consistently, and expensively.

1. Opportunity Cost: The Silent Multiplier

Controls and automation engineers are rarely sitting idle. They are responsible for:

- Supporting daily production

- Maintaining legacy systems

- Improving throughput and quality

- Responding to downtime events

When these same engineers are pulled into a major integration project, something else must give. Maintenance gets deferred. Improvement projects stall. Downtime response becomes reactive.

The business pays for this indirectly through:

- Reduced efficiency

- Increased downtime risk

- Slower continuous improvement

- Higher operational variability

Opportunity cost is rarely budgeted—but it is always paid.

2. Integration Is a Specialised Engineering Discipline

Integration is not simply writing PLC code or connecting devices. It is systems engineering.

It requires deep experience in:

- Multi‑vendor hardware coordination

- Network architecture and segmentation

- Functional safety and compliance

- OT–IT data flow and cybersecurity

- Failure modes, edge cases, and recovery strategies

Most internal teams excel in some of these areas—but very few excel in all. The gaps are filled through trial‑and‑error on live systems, where mistakes have real operational consequences.

Learning curves are expensive when the classroom is a running production line.

3. Debugging Time Scales Nonlinearly

Integration issues compound. A small architectural decision made early can surface weeks later during commissioning, often in ways that are difficult to trace.

Without extensive prior experience:

- Root cause analysis takes longer

- Fixes introduce new issues

- Commissioning timelines stretch unpredictably

What begins as “a few extra days” can easily become:

- Weeks of delay

- Extended downtime

- Rushed compromises that remain in the system for years

This is where the cost of in‑house integration becomes most visible—and most painful.

The Financial Impact of Project Risk

Risk is often treated as an abstract concept, but its consequences are concrete and measurable:

- Missed production targets

- Delayed product launches

- Extended shutdowns

- Emergency contractor support

- Post‑launch rework

When integration is done internally, the organisation carries 100% of that risk. There is no contractual buffer, no external accountability, and no escalation path if the project veers off course.

That exposure has real financial value—even if it never appears on a spreadsheet.

What Expert Integrators Actually Deliver

Hiring an expert integrator is not simply outsourcing labour. It is acquiring experience density—the accumulated knowledge of dozens or hundreds of similar projects.

Beyond project execution, expert integrators also bring the benefit of extensive R&D that has already been completed long before your project begins. Instead of developing tools, standards, and solutions from scratch, you gain access to proven software frameworks, easy‑to‑use programming software, diagnostic tools that automatically track issues, and design refinements shaped by hundreds of previous deployments. These small but critical details—error‑proofing features, intuitive interfaces, optimised logic structures, pre‑validated safety functions, and CE‑compliant design practices—compound into systems that run faster, start-up cleaner, and deliver more reliable production day after day. The quality that comes from mass‑produced engineering, rather than one‑off development, reduces long‑term maintenance effort and ensures the system performs consistently under real‑world conditions. In effect, you are not just buying integration services—you are inheriting years of accumulated engineering investment that would be impractical and costly to replicate internally.

1. Decisions Made Once—Correctly

Experienced integrators have already encountered the failure modes most internal teams have never seen. That experience manifests in:

- Cleaner, more scalable architectures

- Clearer interface definitions

- Maintainable, standards‑driven code

- Robust documentation

These decisions reduce long‑term support costs and make future modifications faster, safer, and cheaper.

2. Predictability and Structure

A strong integrator brings discipline to the project:

- Defined scope and assumptions

- Formal testing and validation

- Controlled change management

- Documented acceptance criteria

Predictability has economic value. Projects that finish on time and perform as specified avoid the cascading costs of uncertainty.

3. Faster Commissioning, Lower Downtime

Because expert integrators have done it before—many times—they commission systems faster and more methodically. This typically results in:

- Shorter shutdown windows

- Fewer startup surprises

- Faster stabilisation after go‑live

For many facilities, avoiding even a few days of lost production can justify the entire integration fee.

Long‑Term Ownership Costs Matter More Than Build Costs

The most overlooked part of the integration decision is what happens after the project is delivered.

Systems built without a cohesive integration strategy often suffer from:

- Inconsistent standards

- Poor or missing documentation

- Fragile logic understood by only one person

- Patchwork architectures that resist modification

These issues quietly inflate the cost of:

- Troubleshooting

- Training new staff

- Adding new equipment

- Scaling production

- Maintaining uptime

Expert integrators design systems intended to be owned—not just installed.

The Hybrid Model: The Most Resilient Approach

The most successful organisations rarely choose between internal and external integration. Instead, they combine the strengths of both.

They:

- Use expert integrators for architecture, complex systems, and high‑risk integration

- Leverage internal teams for day‑to‑day support and incremental improvements

- Require documentation, standards, and knowledge transfer as part of every project

This approach builds internal capability without forcing internal teams to absorb disproportionate risk.

Reframing the Real Question

The question is not:

“Is it cheaper to do this ourselves?”

The real question is:

“What does failure, delay, or rigidity cost us—and how likely is it?”

When integration decisions are evaluated through that lens, the economics shift dramatically.

Final Thought

Automation integration sits at the intersection of engineering, operations, and business performance. Decisions made at this stage echo for years—sometimes decades.

The true cost of integration is not determined by who writes the code, but by how well the system performs, adapts, and supports the business over time.

In that context, the choice between in‑house integration and an expert integrator is not about saving money—it is about protecting value.

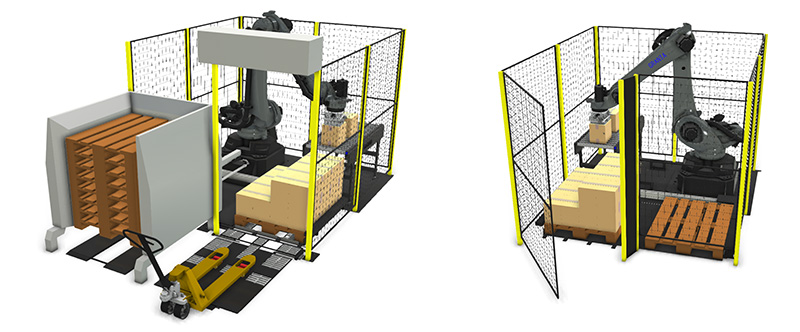

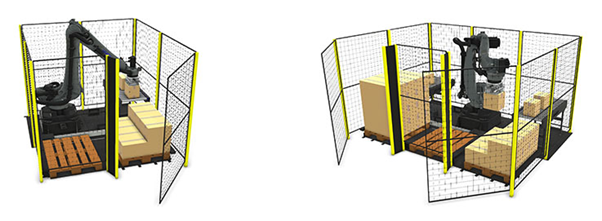

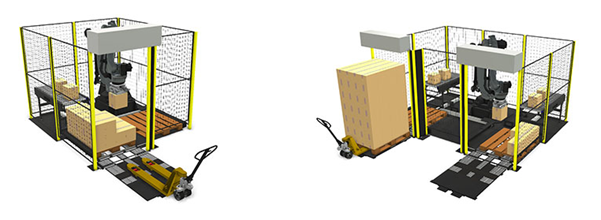

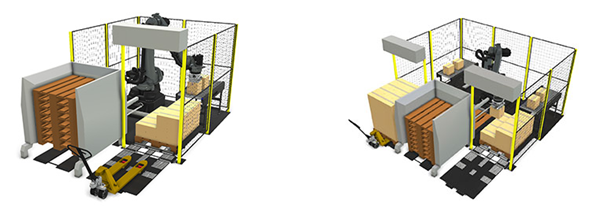

If you’d to discuss you requirements for palletising solutions, feel free to contact us on 01223 499488 or helpline@granta-automation.co.uk and we will be happy to help.

Watch automation videos…

Bag Palletiser

Barrel Palletiser

Box Palletiser

Crate Palletiser

Tray Palletiser

Bag Palletiser

Bag Palletiser

Barrel Palletiser

Barrel Palletiser

Box Palletiser

Box Palletiser

Crate Palletiser

Crate Palletiser

Tray Palletiser

Tray Palletiser