Tel: 01223 499488

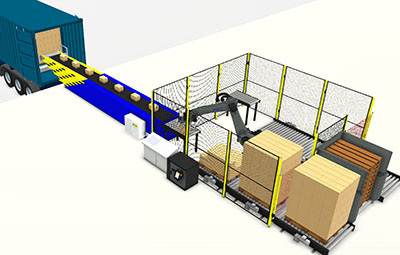

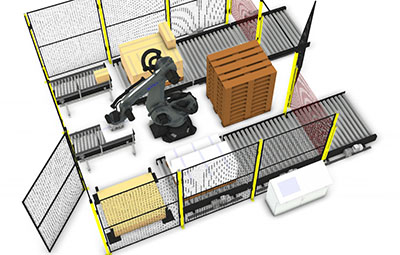

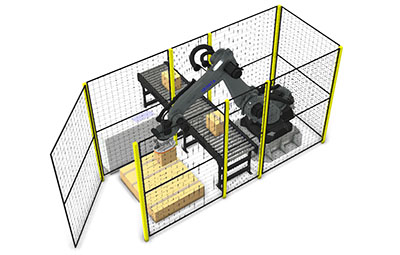

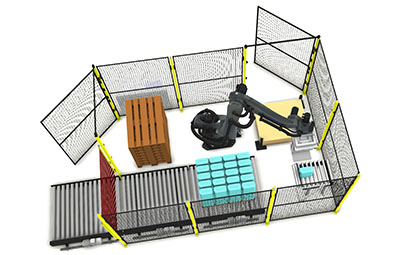

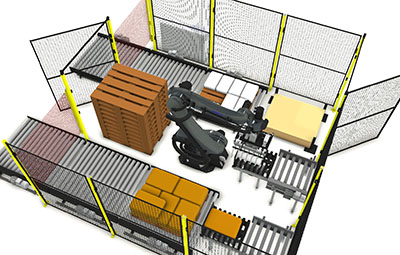

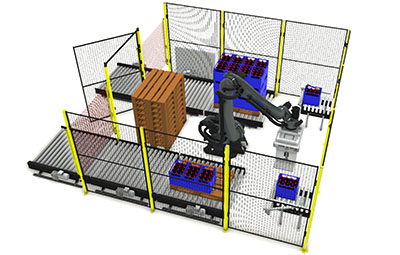

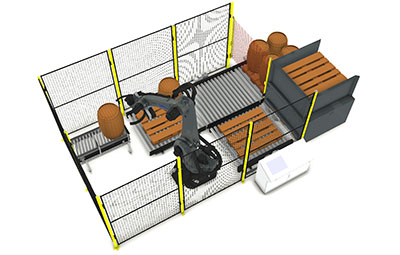

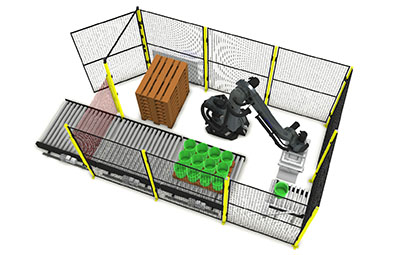

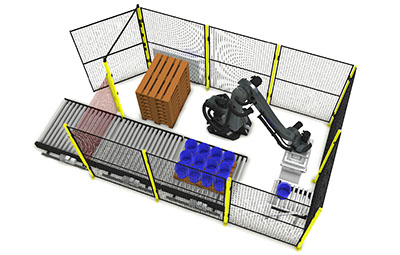

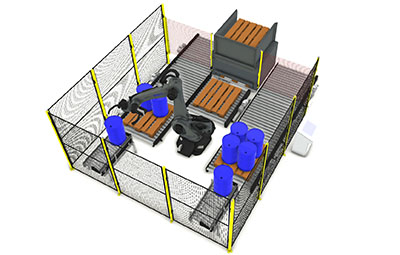

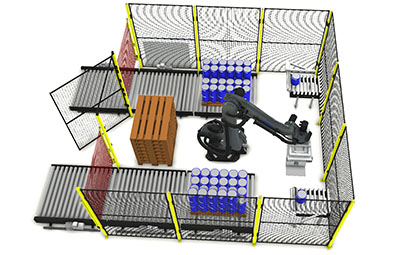

There Are Many Different Palletiser Applications

Introducing automated palletising into your facility will dramatically improve the efficiency of your production process thanks to the many benefits it brings. In the vast majority of cases this can be felt with immediate effect, ensuring you see a tangible return on investment which enables you to recoup your outlay in a relatively short space of time.

To help you with calculating payback on your project, we have created a downloadable resources pack that includes an OEE calculator and automation project payback calculator, along with other useful resources. Click here to download this free resource pack.

The Granta palletising systems are suitable for many different applications. More information on each of these applications is available below. If the application you are looking for is not shown here, then please contact us on 01223 499488 as we also provide bespoke palletising systems, including bespoke grippers.

Achieve new successes, jump ahead of your competition and stay at the cutting edge of your industry.

We look forward to hearing from you!

1 Year Payback

Payback is often less than 1 year due to labour saving, production increase, reduced HR.

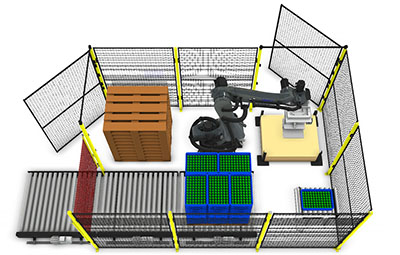

+40% Production Increase

Typically +40% due to: no holidays or breaks, forced takt time, longer working hours, faster speeds etc.

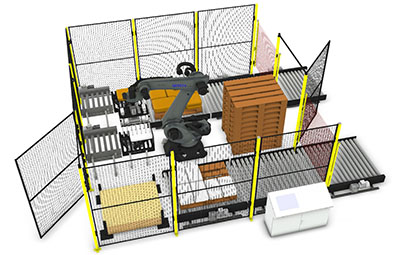

Zero H&S Claims

H&S claims reduced to zero as all manual handing is now done by the robotic palletiser.