Tel: 01223 499488

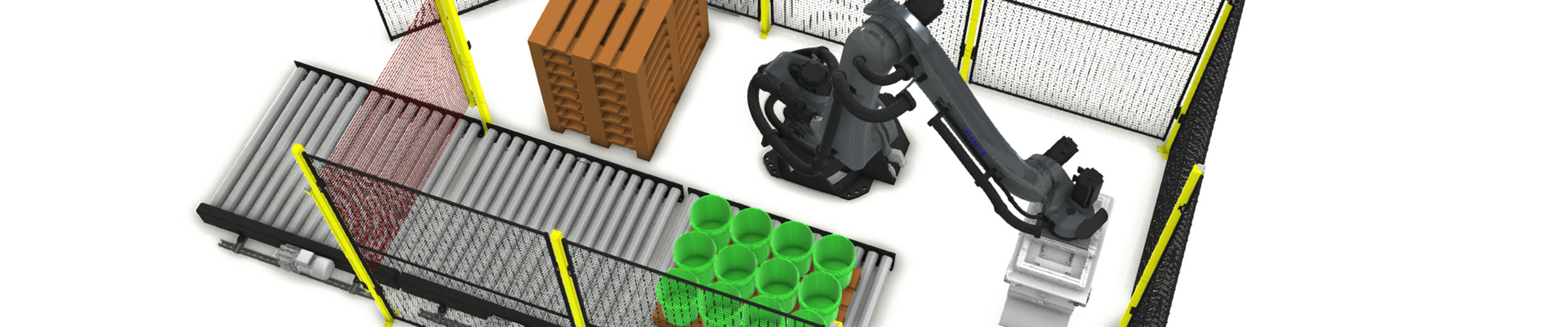

Bucket Palletising System

The Modular and Compact bucket palletising systems are designed for quick installation, low cost, and ease of programming, making them ideal for various production environments.

Both the Modular and Compact palletising series come with user-friendly software that allows your factory floor staff to reprogram the robot within minutes, accommodating different bucket sizes with minimal effort.

The software automatically optimizes bucket stack patterns, helping you quickly select the most efficient layout to maximize pallet usage without extensive planning.

For bucket palletising, an underneath gripper head is typically used. This gripper has a plate that slides beneath the bucket, with an arm that clamps down across the top to securely hold the bucket during lifting. Once positioned, the clamp is released, and the bucket is smoothly pushed off the gripper plate. Additionally, the gripper features an integrated vacuum system for handling pallets and placing slip sheets between layers as needed.

Whether you opt for the Modular series for its extensive customization options or the Compact series for its space-saving design which allows for pallet truck take off, both systems are optimised for your specific process speeds.

Custom modules, such as pallet stretch wrapping and labelling, can also be easily integrated into the Modular palletising series. For more details on our palletiser options, follow the links below.

Stay ahead of your competition with cutting-edge automation solutions. Browse our website or contact us today for help, advice and support with your project.

We look forward to helping you achieve with automation!

1 Year Payback

Payback is often less than 1 year due to labour saving, production increase, reduced HR.

+40% Production Increase

Typically +40% due to: no holidays or breaks, forced takt time, longer working hours, faster speeds etc.

Zero H&S Claims

H&S claims reduced to zero as all manual handing is now done by the robotic palletiser.