Breaking Down the Maths Behind Pick Rates, Patterns, and Productivity

When considering the investment in a robotic palletising system, one of the first questions manufacturers ask is: “How many boxes per hour can it actually handle?”

The answer isn’t a vague estimate—it’s a straightforward calculation based on pick rates and how products are grouped during each pick. While exact performance depends on the product, pallet pattern, and gripper configuration, a few simple examples can give you a clear picture of what’s realistically achievable.

Let’s walk through the maths.

A Conservative Baseline: 330 Picks Per Hour

Although many robotic palletisers are capable of higher speeds, we’ll use 330 picks per hour as a conservative benchmark. This is slower than the typical rate, but provides a solid baseline for planning.

At this pick rate, you only need an average of 2.4 boxes per pick to reach over 790 boxes per hour. Here’s how different stacking patterns affect that outcome:

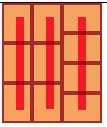

Example 1: 10 Boxes Per Layer

Picked in 3 rows (approx. 3–4 boxes per row)

Calculation:

10 boxes ÷ 3 picks = 3.33 boxes per pick on average

At 330 cycles per hours = 3.33 boxes x 250 picks/hour = 1099 boxes per hour

This is a common, efficient pattern where grouped picks deliver strong output while maintaining stack stability.

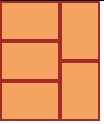

Example 2: 5 Boxes Per Layer

Picked in 2 rows (e.g. 3 + 2 boxes)

Calculation:

5 boxes ÷ 2 picks = 2.5 boxes per pick on average

At 330 cycles per hour = 2.5 boxes x 330 picks/hour = 825 boxes per hour

Even with smaller layers, efficient pick grouping can deliver well over 800 boxes per hour.

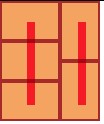

Example 3: 7 Boxes Per Layer

Two options here depending on your tolerance for gaps in the stack:

Option A: Preserve Gaps

Picked in 5 rows

Calculation:

7 boxes ÷ 5 picks = 1.4 boxes per pick on average

At 330 cycles per hour = 1.4 boxes x 330 picks/hour = 462 boxes per hour

Option B: Remove The Gaps

Picked in 3 rows

Calculation:

7 boxes ÷ 3 picks = 2.33 boxes per pick on averageAt 330 cycles per hour = 2.33 boxes x 330 picks/hour = 768 boxes per hour

This example shows how adjusting the pattern can significantly affect throughput—even when the number of boxes stays the same.

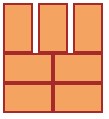

Example 4: 20 Boxes Per Layer

Picked in 4 rows (5 boxes per row)

Calculation:

20 boxes ÷ 4 picks = 5 boxes per pick on average

At 330 cycles per hour = 5 boxes x 330 picks/hour = 1650 boxes per hour

High-volume row picks like this show the power of multi-pick grippers and well-optimised stacking logic.

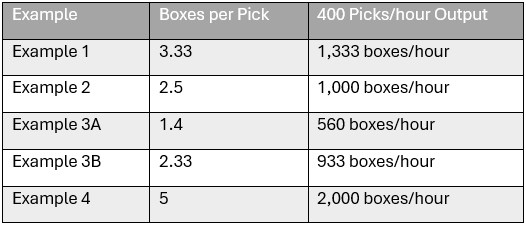

What If the Robot Runs Faster?

In some cases—particularly where boxes are lightweight, uniform, and the gripper is well optimised—robotic palletisers can run at 400 picks per hour or more.

Here’s what that means for each example:

As you can see, the pick grouping and stacking pattern have a much bigger impact on throughput than the robot speed alone.

Key Takeaways

- Pick rate is only part of the story—the number of boxes per pick has a dramatic effect on total output.

- Even with conservative cycle speeds, it’s possible to exceed 800 boxes/hour with basic box grouping.

- Smart gripper design and optimised pallet patterns can more than double throughput in some cases.

- If you’re stacking lighter products with good box quality, higher pick rates (350–400/hr) are often achievable.

- Designing your palletising solution around the right stacking strategy can unlock major efficiency gains.

Thinking About Automating?

At Granta Automation, we design intelligent, fully integrated palletising systems tailored to your products, your space, and your output goals. We help you model your throughput with realistic, data-driven expectations—so you know exactly what to expect before the robot is even installed.

- Palletiser Feasibility Studies

- Gripper Design for Multi-Box Picks

- Full System Integration & Controls

- Intelligent Stack Pattern Software

Call us on 01223 499488 or helpline@granta-automation.co.uk, to request a free system consultation.

Find out more…

- Grantas Portable Cobot Palletising System: High-Performance Automation That Moves With You

- Manual vs. Automatic Palletising: A Comprehensive Comparison

- Manufacturing Efficiency: Why Every Second (and Every Pound) Counts

- The Hidden Costs of Downtime in Food & Beverage Production

- How Robotic Palletisers Deliver Fast ROI for Manufacturers