When integrating collaborative robots (cobots) into production lines, a common and crucial question arises: How fast can my cobot safely operate without physical guarding? The answer hinges on comprehensive risk assessments, adherence to industry standards such as ISO 10218-2 and ISO/TS 15066, and the implementation of appropriate safety measures.

Understanding Safety Requirements

ISO 10218-2, the international standard for industrial robots, does not require physical guarding for cobots but mandates a thorough risk assessment to guarantee safe operation. Cobots come equipped with inherent safety features—such as force and speed limiting controls—that can permit unguarded operation, but only when specific conditions are met.

ISO/TS 15066 complements this by defining precise force and pressure thresholds to ensure safe human-robot interaction. These limits vary depending on the body part involved, recognizing that some areas are more vulnerable to injury:

- Shoulder impact: up to 150 Newtons (N)

- Forearm impact: approximately 50 N

- Head or hand impact: as low as 10–20 N due to increased sensitivity

For a cobot operating in collaborative mode, staying within these force limits is essential to prevent injury.

Running a Cobot Without Guarding

The most straightforward approach to running a cobot without physical guarding is to limit its speed, ensuring that the forces exerted remain within safe boundaries.

- Typical industrial robots operate at speeds up to 2,000 mm/s in non-collaborative modes.

- In collaborative mode, ISO/TS 15066 recommends speeds of 250 mm/s (0.25 m/s) or less to meet safe force requirements, although a risk assessment might permit higher speeds depending on the specific application.

- Practically, if a robot normally processes around 10 boxes per minute at full speed, running in collaborative mode might reduce throughput to roughly 1–1.5 boxes per minute, depending on risk factors and payload.

This speed reduction approach ensures compliance without the necessity for additional physical safety equipment. However, if faster operation is needed, other safety solutions must be explored.

Running Faster Without Physical Guarding

To increase operating speeds without resorting to traditional guarding, manufacturers can integrate safety technologies such as light curtains and area scanners:

- Light Curtains act as virtual safety barriers, automatically slowing or stopping the cobot when someone crosses the beam. Proper safety distance calculations are crucial to maintain worker safety.

- Area Scanners detect personnel approaching the work cell and dynamically adjust cobot speed or halt operations as needed. Their installation requires precise positioning and compliance with Performance Level d (PLd) safety standards.

While these technologies eliminate the need for solid physical barriers, they add complexity to system layout, safety distance management, and control programming.

Final Thoughts

A cobot can indeed operate without guarding, but with important limitations:

- In fully collaborative mode, the cobot’s speed must be significantly reduced to comply with ISO/TS 15066 force limits.

- Light curtains and area scanners provide options for higher speeds without physical guarding but require precise safety measures.

- Comprehensive risk assessments are essential to balance safety, productivity, and regulatory compliance.

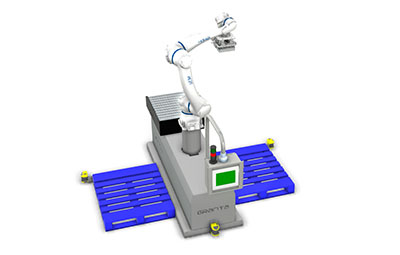

By carefully evaluating your specific application and following the guidelines set by ISO 10218-2 and ISO/TS 15066, you can achieve an optimal balance between efficiency and safety. If you’d like to discuss how Granta Automation can support your cobot integration contact us on 01223 499488 or helpline@granta-automation.co.uk.

Find out more…

- Manual Palletising Wearing You Down? Heres What You Can Do About It

- Rent a Palletiser from Just £2.19 hour Flexible, Fast and Risk-Free Automation

- Beyond Labour Savings: The Unexpected Benefits of Robotic Palletisers

- How to Convince Decision-Makers to Invest in Automation

- Stack Smarter, Not Harder: The Business Case for Robotic Palletisers