Tel: 01223 499488

There Are Many Different Platform Options Available

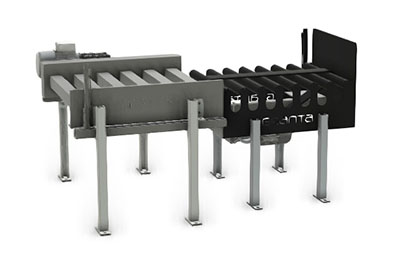

There is a wide variety of standard modular platform options available in the range, with different products on each platform e.g. robot, different types of conveyors, pallet and slip sheet guides etc. Bespoke platform options are also available.

The system can quickly and easily be re-configured, moved or have extra parts added or taken away. The flexibility of this system means that it is very simple to re-configure the system and add extra modules once you have started using it. Altering a traditional palletising system after installation would be very costly.

Some of the different platform module options are shown below.

Robot

Control Panel

Infeed Conveyor

Square Rollers and Sack Pick

Underneath Grip Conveyor

Infeed Bump Turn

Double Infeed Conveyor

Layer Former

Pallet Feeder

Pallet Infeed Stack

Pallet Conveyor

Pallet Transfer Unit

Pallet Turner

Infeed Divert

Infeed Transfer

Static Pallet Position

1 Year Payback

Payback is often less than 1 year due to labour saving, production increase, reduced HR.

+40% Production Increase

Typically +40% due to: no holidays or breaks, forced takt time, longer working hours, faster speeds etc.

Zero H&S Claims

H&S claims reduced to zero as all manual handing is now done by the robotic palletiser.