The number of boxes or bags a palletiser can handle per minute or hour depends on several factors, including the specific model and type of palletiser, the size and weight of the boxes/bags, and the complexity of the stacking pattern. Palletisers are machines used to automatically stack boxes or bags onto pallets for efficient transportation and storage.

There are different types of palletisers, such as robotic palletisers and conventional palletisers, each with its own speed and capabilities. High-speed robotic palletisers tend to have a faster throughput compared to conventional palletisers.

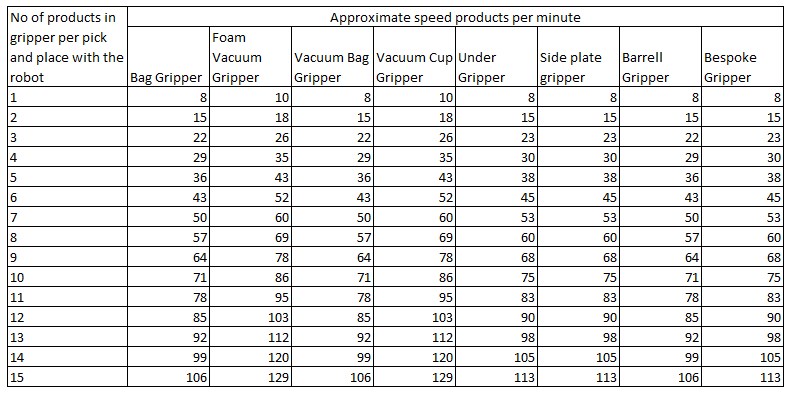

There are also a wide variety of griper head types available on a robotic palletiser, and each of these is able to lift different amounts of product per cycle. Depending on the product and gripper size, robot grippers can pick many products at a time speeding up the throughput of the palletiser, so an accurate calculation of boxes/bags per minute/hour will need to be done for your application to get the specific cycle time for your application.

This table does however show some typical speeds that can be achieve using different gripper types. They are only approximate average speeds and as each application is unique the accurate speeds would need to be calculated based on the application.

The speed that the robotic palletising system can run in products stacked per minute is calculated as follows:

cycles per min with the robot and gripper

X

no of products picked by the gripper each cycle

=

palletising speed in products per minute

To convert boxes/bags per minute (BPM) to boxes/bags per hour (BPH), you can use the following formula:

BPH = BPM * 60

So, for example, a palletiser running at 100 BPM can handle:

100 BPM * 60 minutes = 6,000 boxes/bags per hour

Keep in mind that these numbers are general estimates, and actual performance may vary depending on the specific palletiser and the application. Additionally, the manufacturer’s specifications will provide the most accurate information regarding the palletiser’s speed and capabilities.

There are also several other contributing factors to consider that can affect the speed in addition to the cycle time of the palletising system such inclucing;

- Conveyor speeds

Often the restriction in speeds can be the conveyor system feeding the palletiser. Advanced conveyor systems are required when you get over 25 products per minute in order to control the product flow into the palletiser. An advanced conveyor system will orientate the product correctly whilst keeping it sequenced, and will stop/start as required for feeding into the palletiser system. Whilst a palletiser might be able to run at significantly higher speeds it is essential to get the conveyor system feeding the palletiser correct to enable the optimum performance of the palletising system. - Pallet feeding

Another restriction in speed is the feeding of finished pallets out of the system and the feeding of new pallets into the system. A high speed palletising system will need to have an auto pallet feed system, where the new pallets can be fed into the cell without the palletising system having to stop. This is often done by installing a auto pallet feeder which can be loaded form outside the palletising cell, and will then feed the emptly pallets into the cell via a conveyor system. Filled pallets will also need to be able to leave the palletising cell without the palletiser having to stop palletising. They is typically done using pallet conveyors and light curtains, which enable the pallet to safely leave the palletising cell without the palletiser having to stop. - Slipsheet placement

Another restriction on the cycle time of a palletising cell is the time needed for slipsheet placement. Each slip sheet that is placed creates a break in the palletising process, and reduces the cycle time per hour by the amount of slipsheet placement/time taken to place the slipsheet per hour. Slipsheet placement therefore needs to be taken into account in any cycle time calculations.

If you could like help with calculating cycles times for your process, please contact us on 01223 499488 or helpline@granta-automation.co.uk.